How Often Do Phone Case Printing Vending Machines Need to Be Restocked?

In today's fast-paced world, keeping vending machines stocked is crucial. But how often do phone case printing vending machines actually need restocking?

Phone case printing vending machines require restocking every 1-4 weeks for blank phone cases, depending on sales volume and location traffic. Regular monitoring ensures efficient operations.

Understanding the Restocking Needs

Blank Phone Case Restocking?

Restocking blank phone cases is essential. Yet, it can vary widely based on location and demand, affecting how often restocking is needed.

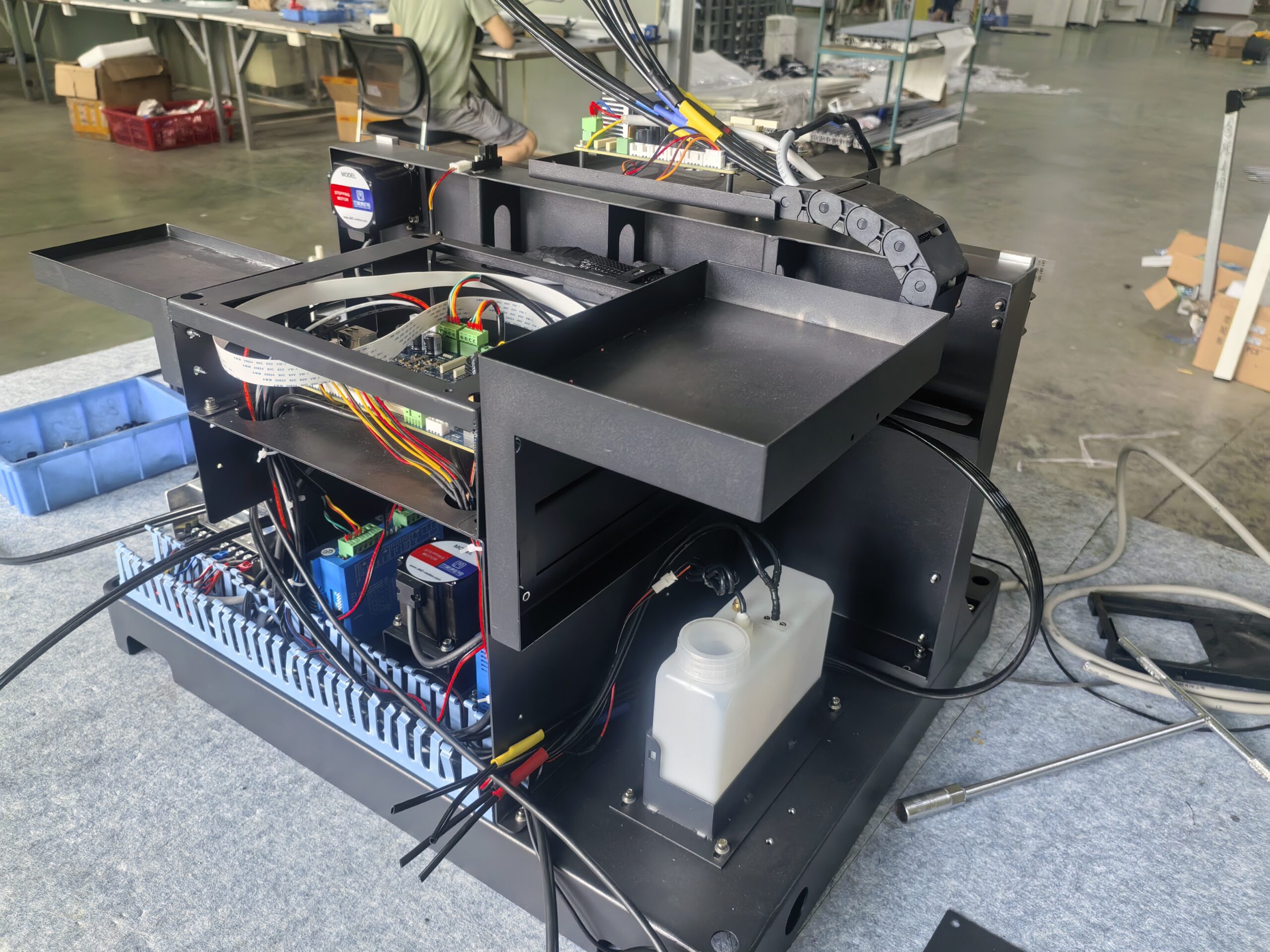

High-capacity machines hold 595 to 630+ blanks, mid-range ones hold 276 to 448. High-traffic areas require restocking weekly, while low-traffic sees monthly needs.

Diving Deeper into Blank Case Restocking

High-traffic spots like malls or airports may sell 20-30 cases daily. Thus, weekly or bi-weekly restocking is common. Moderate spots see 10-20 cases sold daily, needing restocking every 2-4 weeks. In low-traffic locations, 5-10 cases might be sold daily, calling for monthly restocking. Support for up to 96 phone models means flexibility, but also complexity in inventory management.

Printing Supply Restocking?

Apart from cases, ink and supplies also demand attention. The need varies by location's printing needs.

Most machines use 250ml ink cartridges, allowing 640 prints per cartridge. High-volume areas need cartridge replacements every 3-4 weeks.

Diving Deeper into Printing Supply Restocking

Using approximately 0.39ml per case, ink consumption remains efficient. With a 250ml capacity, you can print around 640 cases. High-volume locations will exhaust a cartridge in 3-4 weeks; moderate ones in 1-2 months, and low-volume places every 2-3 months. Remote alerts track ink levels, easing the management burden.

Daily Maintenance Needs?

Daily maintenance is minimal but important. Routine tasks ensure smooth vending operations.

Operators usually spend under 30 minutes daily on checks and basic cleaning. This keeps the machines in good shape.

Diving Deeper into Daily Maintenance

Operations include checking supply levels, monitoring print quality, cleaning touchscreens, and reviewing sales data. Consistent maintenance ensures quality service and longevity. With real-time alerts on supply and technical status, remote systems help operators maintain efficiency without constant physical presence.

The Role of Location and Season?

Location type heavily influences restocking demands, as do seasonal shopping patterns. Different places pose unique restocking challenges.

Airports and malls require more frequent restocking due to high footfall compared to office settings. Seasonal spikes, like holidays, increase demands.

Diving Deeper into Location and Season Factors

Shopping centers, bustling with impulse buyers, demand frequent restocking. Universities, especially during term times, also see high activity. Airports, with constant traveler turnover, need regular attention. Meanwhile, office locations present more steady, albeit lower, demand. Holidays and tourist seasons amplify needs, requiring extra preparatory efforts.

Phone case printing vending machines need frequent restocking, with variations based on location traffic and seasons. Regular monitoring ensures smooth operation.