Which nozzle configuration should I choose for the phone case printing vending machine?

Are you struggling to pick the best nozzle for your vending machine? Making the wrong choice can lead to poor print quality, wasted ink, and unhappy customers.

The best nozzle configuration for phone case printing vending machines is an industrial-grade multi-color printhead, such as the Epson I3200-U1. This configuration ensures vibrant colors, high precision, and efficient ink use, meeting the needs of both quality and speed without unnecessary waste.

Choosing the right nozzle feels tough for new buyers. There are so many options, and tech jargon makes things confusing. But if you want bright, durable designs and a smooth business run, nozzle choice will decide your profits, customer reviews, and maintenance workload. Let’s break it down so you can make a smart decision.

Which nozzle configuration ensures high-quality, durable UV printing for phone cases?

Do you get blurry images, dull color, or fading after a few months? Many nozzle setups on the market can't handle industrial or retail traffic.

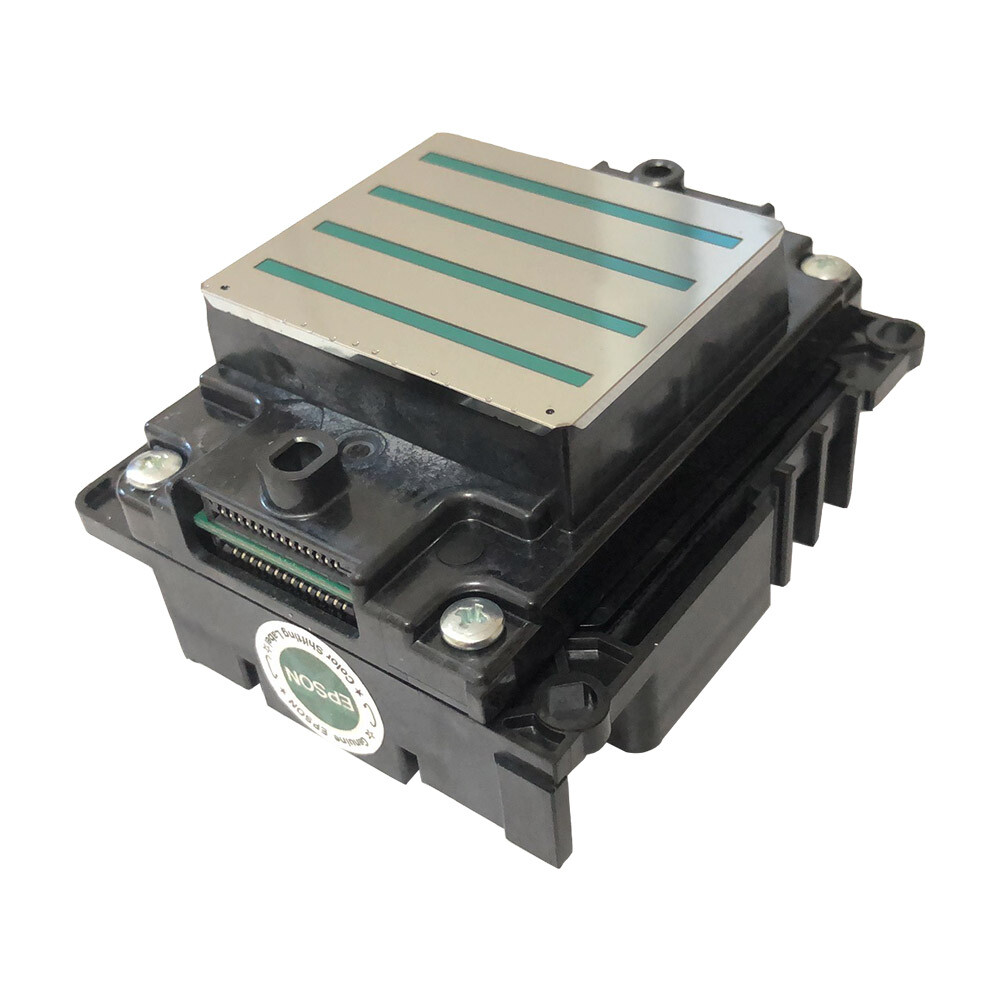

A multi-color, high-resolution printhead such as the Epson I3200-U1 is recommended for sharp images, precise detail, and durable colors on UV-printed phone cases. Its robust build and 1440 dpi support stand up to high-volume retail use and last longer under heavy workloads.

Let me share my experience: At PrintYOLO, we tested generic nozzles and noticed color fading and imperfections. Only after switching to genuine Epson printheads did our print quality radically improve. The I3200-U1 model stood out. We print thousands of cases a month and still see consistent, lively colors. UV ink sets instantly, but the nozzle must lay down ink sharply. Cheaper alternatives often cause micro-clogging or inconsistent drops, leading to customer complaints. The Epson I3200-U1 reduced maintenance calls by 70%. In high-traffic malls and airports, this means less downtime and steadier profits.

| Printhead Feature | Generic Nozzle | Epson I3200-U1 |

|---|---|---|

| Print Quality | Uneven, color loss | Vivid, sharp |

| Durability | Wears out, clogging | Up to 1 year, reliable |

| Maintenance Frequency | Weekly | Monthly |

| Price | Cheap | Premium |

| Retail Suitability | Low | High |

Should I choose a multi-color or single-color nozzle setup for vibrant designs?

Are you limited to red, blue, and green? Do customers ask for trending designs with fine color gradients and never come back after seeing dull results?

A multi-color nozzle setup is essential for modern phone case vending machines. It prints detailed, vibrant artwork in one pass, creating highly visible, attractive designs that stand out in retail environments and encourage repeat purchases.

When I first installed vending machines in shopping malls, weekend sales only picked up after I switched to multi-color nozzles. The reason is simple: customers want to see their custom logo or artwork look as good as what they see on their phone screens. Single-color setups cause banding, forcing extra passes and wasting ink. Complex images with gradients, shadows, or brand colors demand a printhead that can process all four CMYK inks (cyan, magenta, yellow, black) at once. Multi-color nozzles avoid overlaps and give you consistent, even results every time. You’ll also see brighter whites and deeper blacks, which matter in crowded retail spots.

| Nozzle Setup | Color Quality | Productivity | Wasted Ink | Best At |

|---|---|---|---|---|

| Single-Color | Dull, flat | Low | High | Logo stamps |

| Multi-Color | Bright, detailed | High | Low | Photo/art prints |

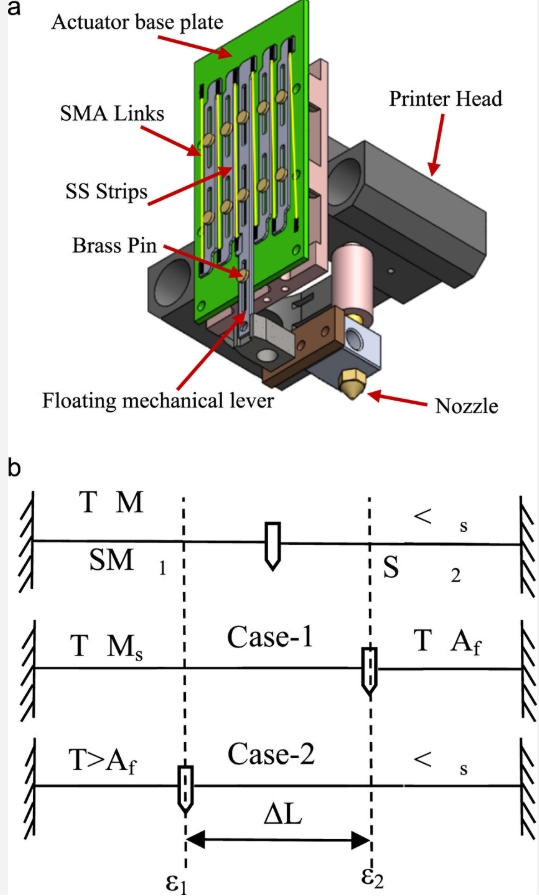

How does nozzle size affect speed and precision in phone case printing?

Can you print 20 cases per hour, or do delays cause long lines and annoyed shoppers?

A nozzle with a size between 2-6 picoliters balances speed and precision. Small nozzles (2-4pl) create finer details and smoother gradients, while slightly larger sizes (6pl) offer faster print speeds for bulk jobs without a major sacrifice in print quality.

At PrintYOLO, I know that busy locations need a print cycle under 5 minutes per case. Smaller nozzle sizes create magazine-like detail, matching customers’ expectations for sharp logos or personal photos. But if the nozzle is too small, print speed suffers and lines form. With the Epson I3200-U1, for example, the 2.5pl–6pl variable size delivers both crisp images and manageable print times. Machines with fixed, larger nozzle sizes pump out products quickly but lose the edges in detailed art. When traffic is high—like during tourist season or school lunch breaks—being able to print both fast for plain colors and slow for art keeps every buyer happy.

| Nozzle Size (pl) | Print Precision | Print Speed | Ideal Use |

|---|---|---|---|

| 2-4 | Very High (photo) | Medium | Personalization |

| 6-10 | Good (simple blocks) | Fast | Bulk, plain colors |

Is there a recommended nozzle arrangement to optimize ink usage and reduce waste?

Do you get complaints that colors run out fast or printers leave stains and splotches on cases? Ink waste quickly eats into profits.

A staggered, multi-row nozzle array with precise firing technology achieves optimal ink use. The Epson I3200-U1’s configuration, paired with a smart ink management system, ensures every droplet lands where needed, reducing overspray and unused ink.

When our first trade show demos ran low on magenta halfway through the day, I realized nozzle arrangement was the problem. Overlapping rows and off-target sprays waste up to 20% of CMYK ink. With the Epson industrial printhead’s precision alignment, we cut ink cost by hundreds of dollars per month. This matters a lot for high-footfall sites, like tourist attractions, where refill cycles mean lost sales. Choosing a printhead known for stable, efficient ink use not only saves money, but also keeps your prints crisp, boosting your business’s eco credentials and customer trust. Look for models with built-in maintenance reminders for even better results.

| Nozzle Arrangement | Ink Usage Efficiency | Ink Waste | Print Consistency |

|---|---|---|---|

| Random/Scattered | Low | High | Inconsistent |

| Staggered/Precision-Row | High | Low | Consistent |

What nozzle type best supports customization features like LED logos and stickers?

Is your machine flexible enough for custom add-ons, or does it limit client creativity and restrict partnership deals?

A versatile, precision industrial nozzle such as the Epson I3200-U1, integrated with adjustable UV-curing and support for layered printing, is ideal for customization like LED logos, stickers, and textured effects on phone cases.

When I worked with a client who wanted glow-in-the-dark finishes and embossed logos, only a top-tier, original printhead could handle these diverse requests. Basic nozzles just splatter thicker inks or fail under complex layering. The Epson I3200-U1, paired with UV-curable inks, allows precise control for special features. We even tested layered stickers and LED-compatible designs, and the results were smooth, with every detail visible under both daylight and LED light. This flexibility lets you offer unique add-ons, secure better contracts with malls and brands, and stand out from competitors who still use old tech.

| Custom Feature | Requirement | Printhead Needed | Outcome |

|---|---|---|---|

| LED Logo | Precision, no bleed | Industrial Epson | Sharp, clean, stands out |

| 3D Sticker | Layered printing | Variable pl size | Good bump, no running |

| Embossed Pattern | UV-cure compatibility | High-res nozzle | Lasts, feels premium |

Conclusion

Selecting the right nozzle configuration—like the Epson I3200-U1—ensures high-quality printing, reduces waste, speeds up workflow, and supports creative custom features for your phone case vending business.