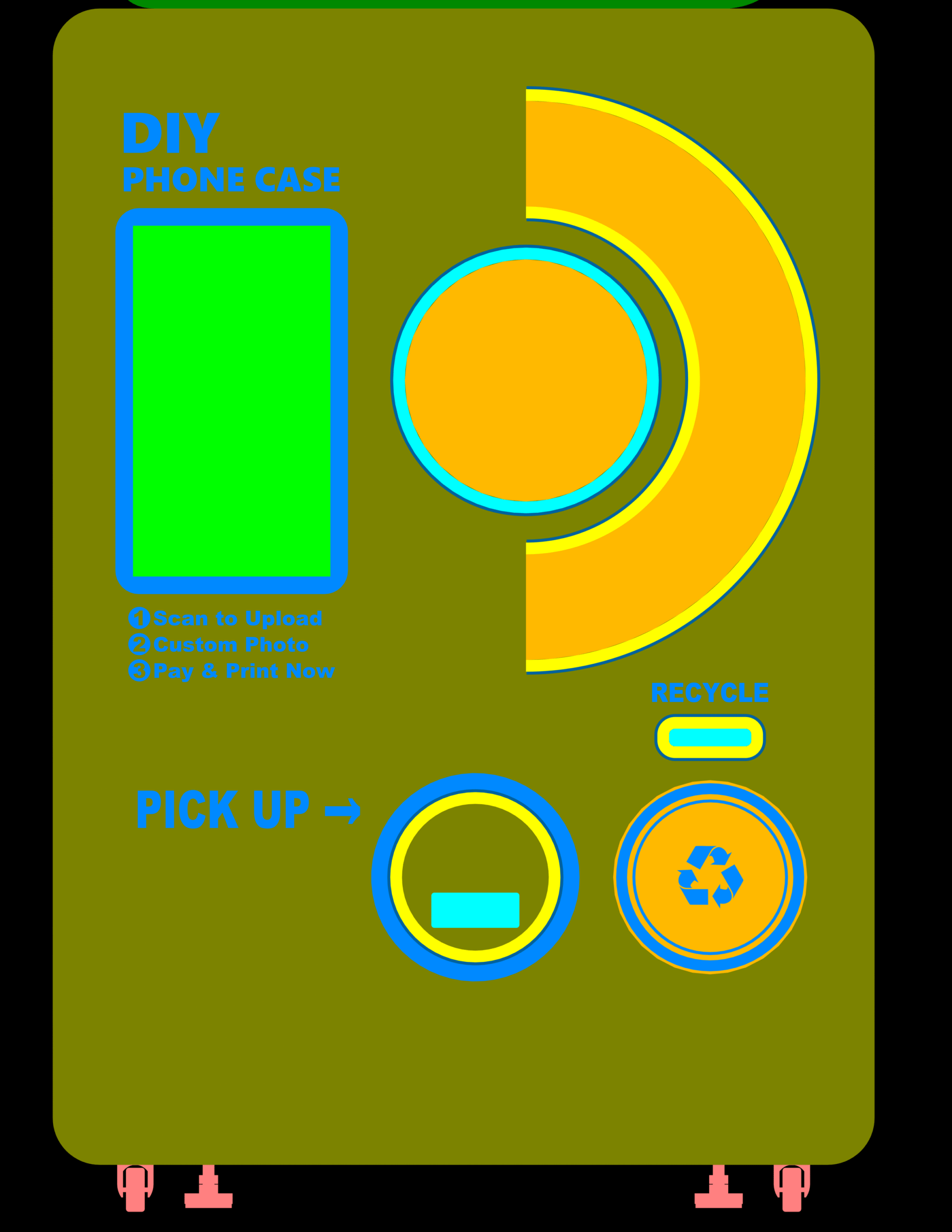

What kind of material is best for the phone case printing vending machine?

Not all phone case materials work well in self-service printing vending machines. The wrong choice can cause blurry images, ink peeling, or cases that break after a few weeks.

The most suitable materials for phone case printing vending machines are TPU, PC, and cases that combine these materials with magnetic attachments. These materials perform well with UV printing and deliver vivid, durable designs that meet most retail and B2B needs.

Choosing the right material makes all the difference. If you get it wrong, customers may return with complaints about fading prints or cracked cases. Let’s look at which options deliver the best results and keep your vending business running smoothly.

What materials are used for the phone cases printed by the vending machine?

Ever wonder if you need to use special phone cases for the vending machine? Quality depends on what you print on.

Phone case vending machines most commonly use TPU (thermoplastic polyurethane), PC (polycarbonate), or hybrid TPU+PC cases. Newer models also support phone cases with built-in magnetic attachments for MagSafe features.

I remember dealers asking if they could just use “any case from the market.” That did not go well. Generic rubber or leather cases often absorbed ink or warped after UV curing. After dozens of tests at PrintYOLO, I found that TPU has the right amount of flexibility, helping absorb minor shocks. PC gives structure and protection. By combining both, hybrid TPU+PC cases offer a soft grip and sturdy frame without ink bleed or cracking. When we added magnetic ring options for iPhone MagSafe, those cases also printed bright, sharp designs and fit retail demand. Some metals and soft silicones never bonded well, leading to dull images or smudged prints.

| Material | UV Print Quality | Durability | Consumer Appeal |

|---|---|---|---|

| TPU | Good | Flexible, strong | High |

| PC | Excellent, vivid | Rigid, protects | Very high |

| TPU+PC | Superior, balanced | Both benefits | Highest |

| Magnetic Hybrid | Very good | Modern, versatile | Grows yearly |

| Soft Silicone | Poor, smudgy | Warps, stains | Low |

Does the vending machine support printing on plastic, metal, or other case materials?

Can you print on anything, or are you forced to use only basic plastic cases? Getting this wrong could upset customers who want variety.

Most vending machines, like those at PrintYOLO, are designed for optimal results on plastic-based materials—TPU and PC. Metal, soft silicone, and some rubberized cases do not support UV or inkjet printing reliably and usually fail quality standards.

When I first branched into high-end mall locations, clients requested aluminum cases to match “premium” branding. That seemed like an easy upsell but left us with peeling prints and support headaches. Our machines, and most others on the market, control ink cure and adhesion for plastics. Metals require special primers and ink formulations, which increase cost and slow print time. While some advanced machines can print on pre-treated metals, you risk wear, fading, or poor image quality. For day-to-day vending business, sticking with PC, TPU, and their hybrids guarantees beautiful, lasting results. If you want to expand materials, ask your supplier about compatible upgrades.

| Material Type | Vending Support Level | Print Quality |

|---|---|---|

| TPU/PC/Hybrid | Full | High |

| Metal | Limited/Requires prep | Low-Medium |

| Silicone/Rubber | Not supported | Poor |

Are UV printing and inkjet technology compatible with specific phone case substrates?

Does UV printing work for every type of phone case? Is there a risk of ink not sticking, or prints getting scratched off?

UV and inkjet printing work best with non-porous, smooth substrates such as PC, TPU, and their composites. They deliver high-resolution images with vibrant colors. Textured, oily, or porous cases—like untreated silicone—are less compatible, leading to smudging, poor adhesion, and quick fading.

After testing several hundred case batches, I learned that ink must sit on the surface, not soak in. Polycarbonate (PC) offers a perfectly flat printing plane, allowing UV-curable inks to bond instantly under the light. TPU holds detail, even for complex or layered prints. Hybrids ensure both color pop and drop resistance, keeping customer satisfaction and repeat sales high. Cheaper plastic blends or soft, matte finishes often “drink” too much ink or repel it, so you get patchy colors, cracks, or short-lived images. My advice: if you want lasting, sharp graphics, always use high-quality PC or TPU-based blanks.

| Substrate | UV Printing Quality | Inkjet Adhesion | Lifespan |

|---|---|---|---|

| PC | Excellent | Excellent | 2+ years |

| TPU | Good | Good | 1–2 years |

| Hybrid (TPU+PC) | Excellent | Excellent | 2+ years |

| Silicone/Other Blends | Low | Poor | Weeks/months |

How durable and waterproof are the printed designs on different case materials?

Will your custom print peel off after a month, or can it survive the daily drops, spills, and sun exposure that happen in real life?

Printed designs on PC and TPU+PC hybrid cases are highly durable and waterproof when made with UV inkjet technology. Colors stay bright, and the graphic layer resists scratches and washing. Silicone, fabric, or coated cases usually fade, bleed, or lose prints after weeks of use.

I remember one customer who ran an outdoor booth asking if prints would survive a summer rainstorm. With UV-cured inks on PC or hybrid cases, water beads straight off, and prints stay good-as-new even after months in pockets, bags, or heat. TPU allows a little flex that protects against cracking. In our after-sales surveys, PC/TPU-printed designs scored 9/10 on scratch resistance, while silicone or imitation leather dropped to 3/10. When you stick with “factory-recommended” blanks, customers rarely complain about peeling, dullness, or sticky prints later.

| Case Material | Durability | Water Resistance | User Satisfaction |

|---|---|---|---|

| PC | Very high | Excellent | High |

| TPU | High | Excellent | High |

| TPU+PC | Top level | Excellent | Excellent |

| Silicone/Fabric | Low | Poor | Low |

Can I customize the material of my phone case before printing with this machine?

Want to offer premium, eco, or magnetic phone cases on demand? Or are you stuck with whatever blanks the machine supplier gives you?

Most phone case printing vending machines are optimized for blank TPU, PC, or hybrid cases. Some advanced models let operators load pre-selected blanks like magnetic ring cases for MagSafe, but do not support on-the-fly material customization by the end-user. For full customization, you must use OEM/ODM services to source and pre-load custom blanks.

From my experience, mall operators and creative shop owners choose styles (basic clear, black-out, magnetic, bumper) and pre-load the vending machine. End users cannot load their own materials for safety and print quality reasons—every blank needs to be flat, certifiably safe, and compatible with UV ink. For larger retail partners, we offer bespoke batches. This way, you can choose anti-microbial, extra-grippy, or eco-friendly cases for special events, but these must be stocked and matched to the vending system ahead of time. This keeps machines running smoothly and makes sure prints last as promised.

| Customization Option | Supported by Standard Machine | Requires OEM/ODM | End-User Choice |

|---|---|---|---|

| Blank TPU/PC | Yes | No | No |

| Hybrid/Magnetic | Yes | No | No |

| Eco/Specialty | No | Yes | No |

Conclusion

TPU, PC, and TPU+PC hybrid phone cases with optional magnetic features are the best choices for vending machine UV printing. They keep prints vibrant, tough, and waterproof, ensuring happy, returning customers.