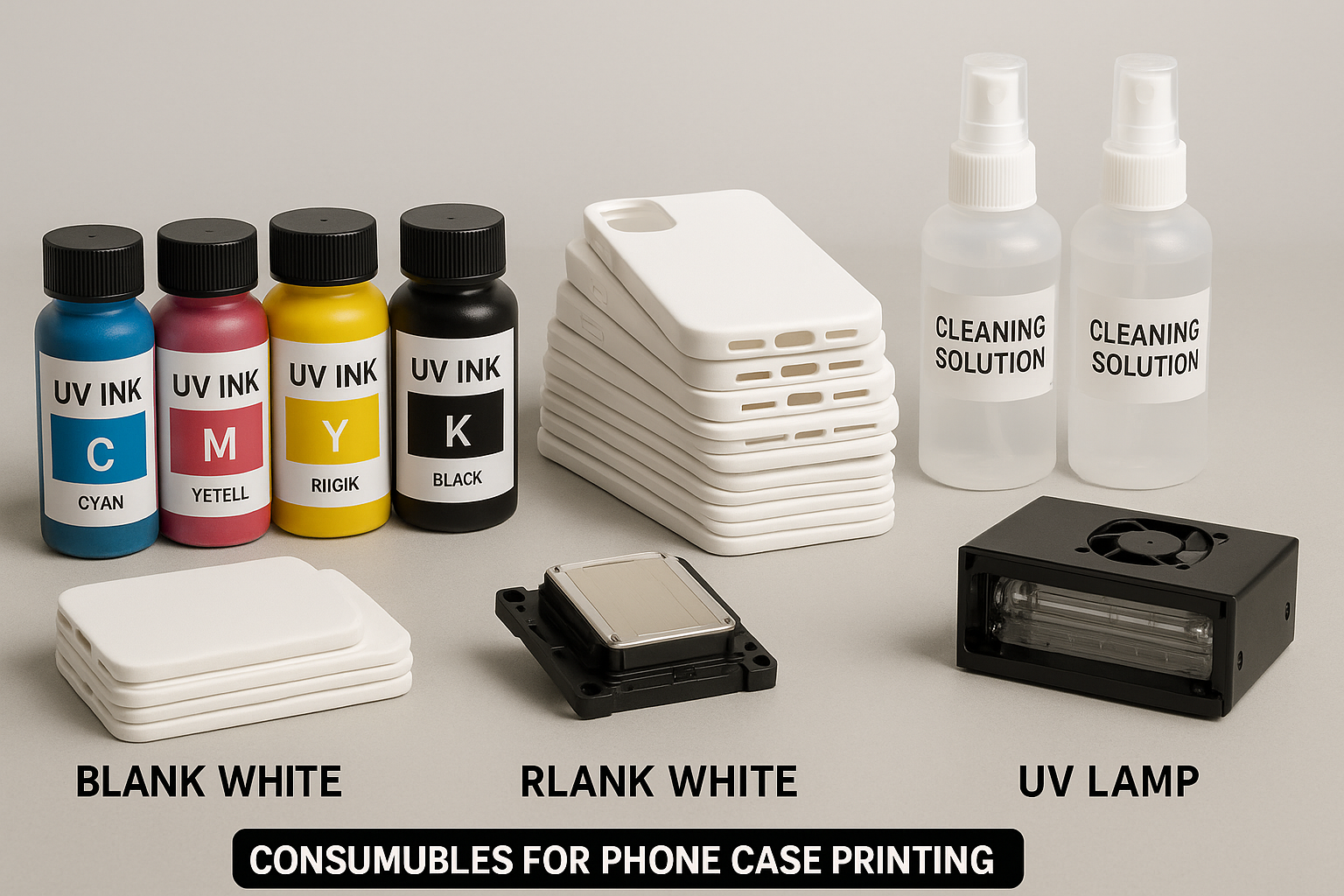

What Are the Common Consumables for the Phone Case Printing Vending Machine?

Are you constantly running out of supplies for your phone case printing vending machine and unsure what you really need to keep on hand? Let’s clear up the confusion.

The main consumables for a phone case printing vending machine are UV inks, coated phone case blanks, cleaning solutions, and parts like printheads and UV lamps. Each plays a crucial role in delivering strong, vibrant, and long-lasting prints.

Many owners and operators underestimate the importance of the correct consumables for reliable, high-quality output. I have seen businesses come to a halt just because they overlooked small items like cleaning fluid or ran cases not compatible with the ink. Let’s look in detail at what you need, how to choose the right supplies, and how to minimize downtime and waste. If you want trouble-free production and consistent results, this guide is for you.

What Specific Inks Are Used as Consumables in the UV Printing Process for Phone Cases?

Struggling to get bright, durable prints or unsure which inks work best? You are not alone in this challenge.

Phone case printing vending machines use UV-curable inks, available as soft, neutral, and hard variants. These inks cure quickly under UV light and adhere well to flexible and rigid phone case materials.

Soft UV inks are designed for flexible cases like TPU and silicone, so they bend without cracking. Neutral UV inks work for most hybrid or composite cases, offering a balance of durability and flexibility. Hard UV inks are sometimes used for rigid plastic or metal, mostly for decorative inlays. The most common ink cartridges or tanks for machines like the Pic Case O hold about 2000 ml. Always match ink type to your blank’s material and your printer model, as using the wrong ink can cause fading or poor adhesion, especially on the latest devices.

How Much Ink Does the Pic Case O Vending Machine Typically Use Per Print?

Worried about running out of ink sooner than expected? Tracking ink use is easier than you think.

The Pic Case O vending machine usually uses 1.5–2.5 ml of ink per phone case print, depending on design coverage and colors. Full-color, edge-to-edge prints require the most ink.

Ink consumption varies by print area coverage and color intensity. For example, printing a white background or heavy black blocks may use more ink than light pastel tones or simple patterns. I log every refill, and for an average booth doing 100 cases per week, a single 2000 ml ink tank lasts just about three–four months. To manage stock well, monitor ink levels with the remote management system, and keep an extra ink set ready. Here’s a quick breakdown:

| Print Type | Ink per Case (ml) | Cases per 2000 ml Tank |

|---|---|---|

| Light, minimal design | ~1.5 | ~1333 |

| Full-coverage, vibrant | ~2.5 | ~800 |

| Custom photo/graphics | 1.8–2.2 | 900–1110 |

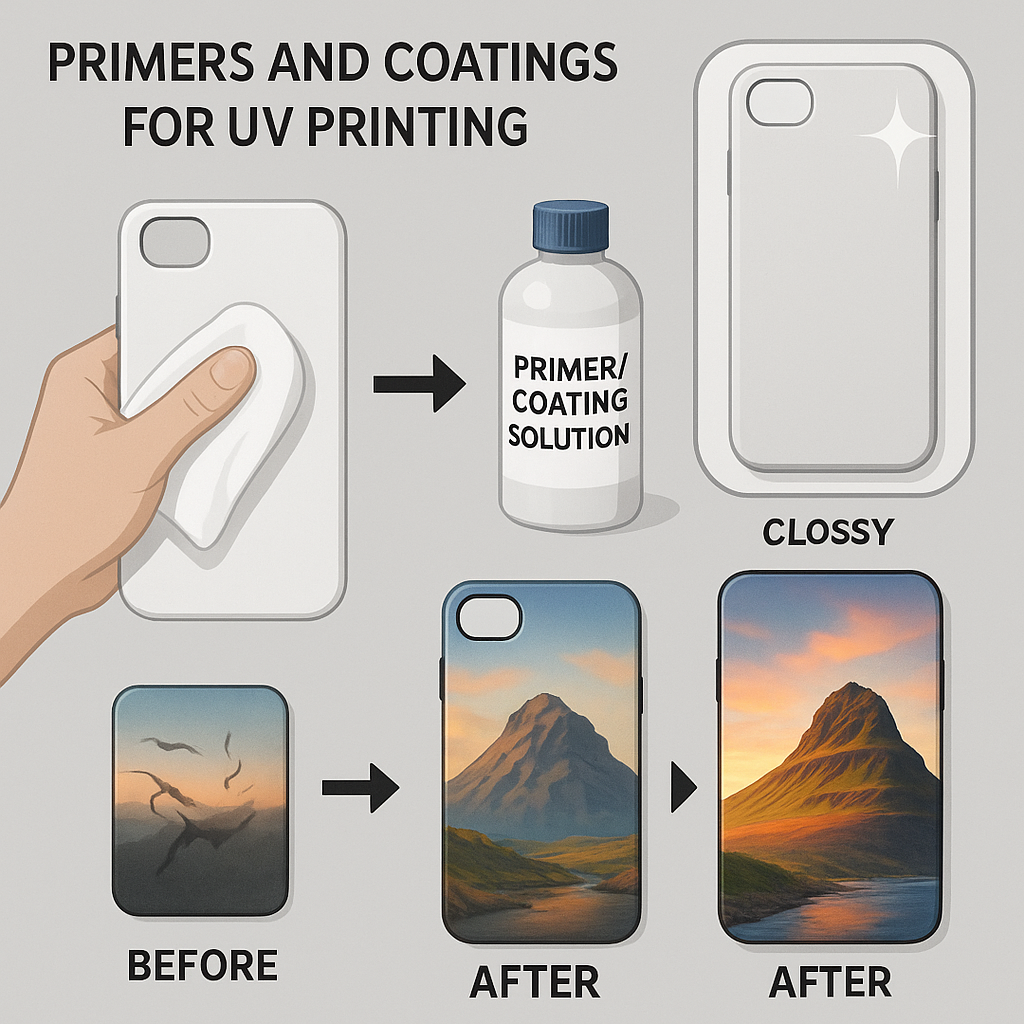

Are There Special Coatings or Primers Needed Before Printing on Phone Cases?

Ever had prints peel or scratch too easily? Proper pre-treatment solves most of these problems.

Some phone case blanks require primed or coated surfaces before UV printing to ensure ink adhesion. Most high-quality blanks come pre-coated, but always check manufacturer details.

The majority of blank phone cases for vending machines ship with a glossy, UV-reactive coating already applied by the supplier. This layer lets ink bond properly and creates sharp images. If your supplier sends uncoated or semi-finished blanks, you may need to spray or wipe on a primer before loading them into the machine. Missing this step often leads to blurry images, edges peeling up, or smudges after printing. Always peel away the protective film coating (if any) before putting the blank in the printer. For metal inserts or extra-gloss cases, a clear top-coat may be applied post-print to enhance scratch resistance.

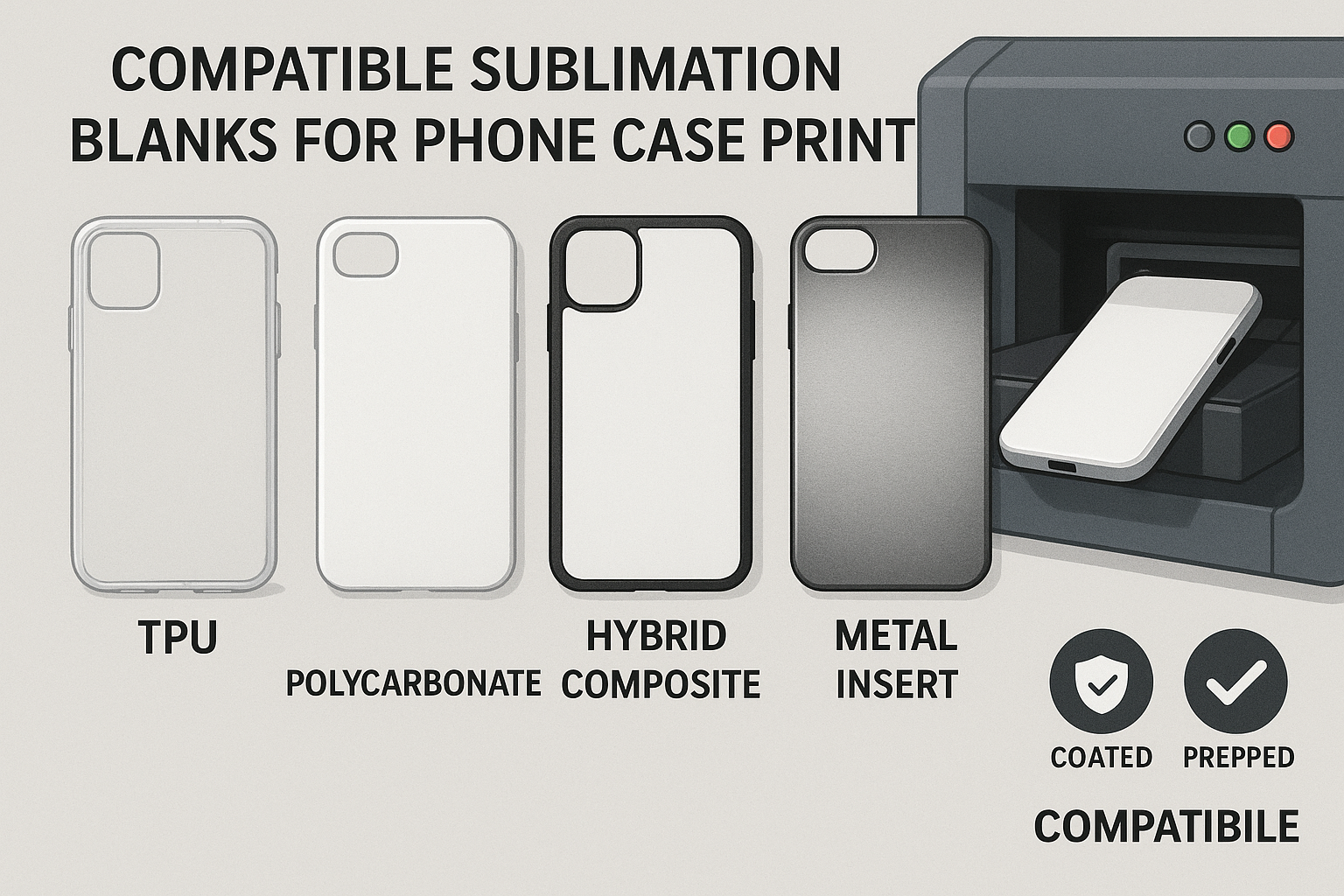

What Types of Sublimation Blanks Are Compatible with the Vending Machine's Printing Process?

Confused by which cases and blanks work with your machine? Compatibility matters for vibrant, lasting output.

Compatible blanks include TPU, polycarbonate, and hybrid composites, pre-treated for UV ink. The vending machine supports up to 85 case types—commonly iPhone, Samsung, and other high-volume Android models.

TPU is the most popular for its flexibility and shock absorption, but hard plastic, hybrid, and select silicone blanks are also widely used. All blanks must fit your machine’s size templates (usually 85–100 SKUs for flagship and popular models). Use blanks that arrive with a pre-applied, print-compatible coating on the image surface, or you risk print failure. Some vendors also sell special blanks with unique textures (e.g., leather look), or metallic inlays for premium designs. Here is a quick guide to matching blanks and ink:

| Blank Material | Compatible Ink Type | Special Needs |

|---|---|---|

| TPU/Silicone | Soft UV | Pre-coated, peel film |

| Polycarbonate/ABS | Neutral or Hard UV | Pre-coated, smooth |

| Hybrid/Composite | Neutral UV | Test sample first |

| Metal Insert | Hard UV + Adhesive | Use primer, strong hold |

How Often Do the Ink Tanks Need Refilling During High-Volume Phone Case Production?

Running low on ink during rush hour is every operator’s nightmare. Here’s how to avoid that.

For high-volume production, ink tanks (2000 ml) in the vending machine need refilling every 700–1000 prints. The actual frequency depends on print size, coverage, and ink efficiency.

On busy days with constant orders, tanks can run dry in a week or two if the machine is popular. I have handled installations where event peaks (e.g., graduations on campus) pushed output over 200 cases per day, causing daily ink top-ups. Most vending printers track ink in real time, so keep a watch on the dashboard and stay stocked with enough ink and cleaning fluid for at least double your weekly average. For best results, clean the printhead with proper solution every time you refill. Replace the UV lamp and optical filters every few months to avoid under-cured, easily scratched prints.

Conclusion

Choose the right UV inks, coated blanks, and cleaning supplies for smooth, reliable phone case printing. Track stocks regularly and you will avoid missed sales from low consumables.