How Much Electricity Does a Phone Case Printing Vending Machine Use?

The cost of running vending machines keeps many business owners up at night. With rising electricity prices, understanding power consumption before investing in a phone case printing machine is essential for accurate profit calculations.

Phone case printing vending machines typically consume between 300W and 500W during active printing and 150W to 180W in standby mode. For a machine operating 8 hours daily with 16 hours in standby, this translates to approximately 3-5 kWh per day or 1,000-1,800 kWh annually, costing $150-270 per year.

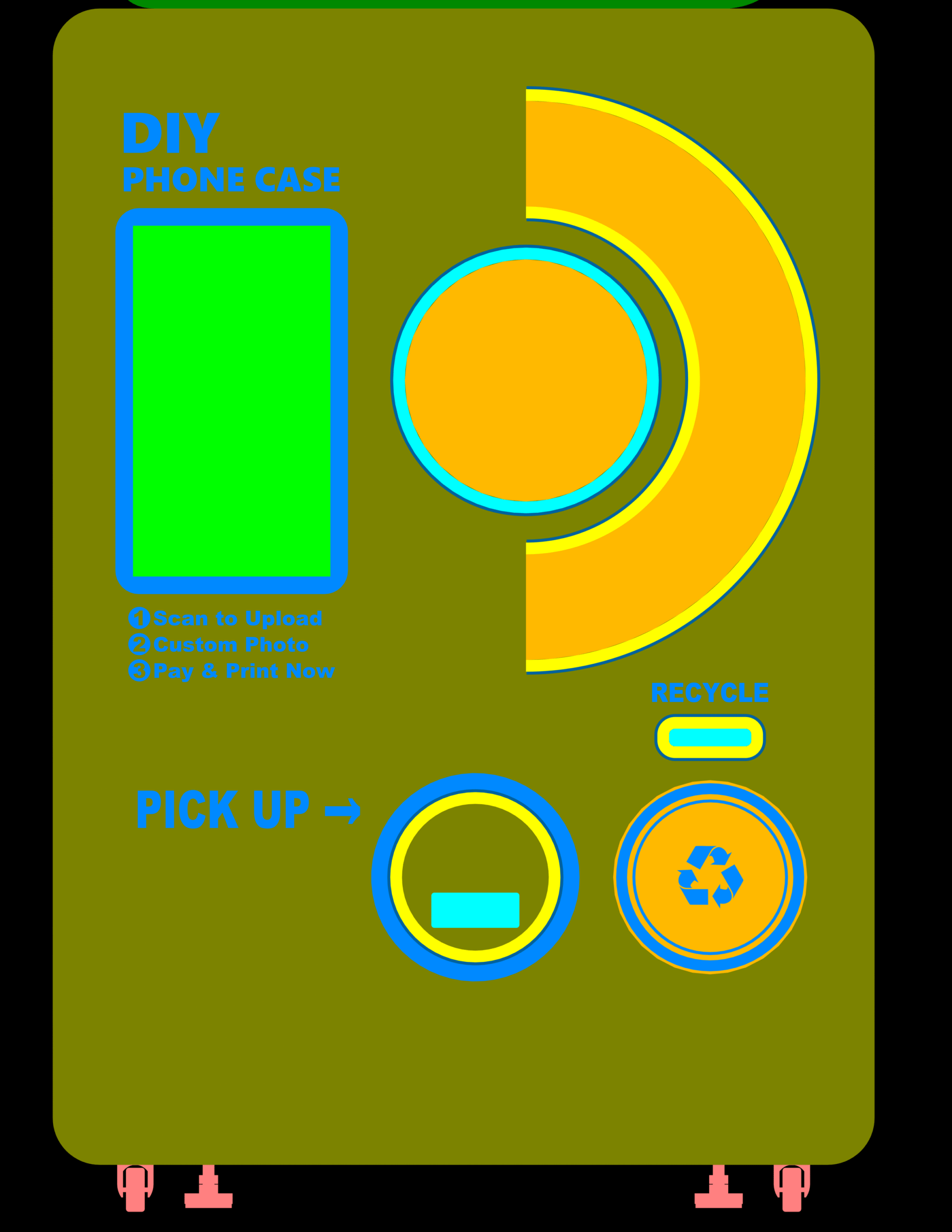

I've had many customers ask me about power consumption when considering our PrintYOLO machines. It's a smart question, as electricity costs directly impact your bottom line. Let's break down exactly what you need to know about the power requirements of these innovative retail solutions.

What Are the Typical Power Ratings of Phone Case Printing Machines?

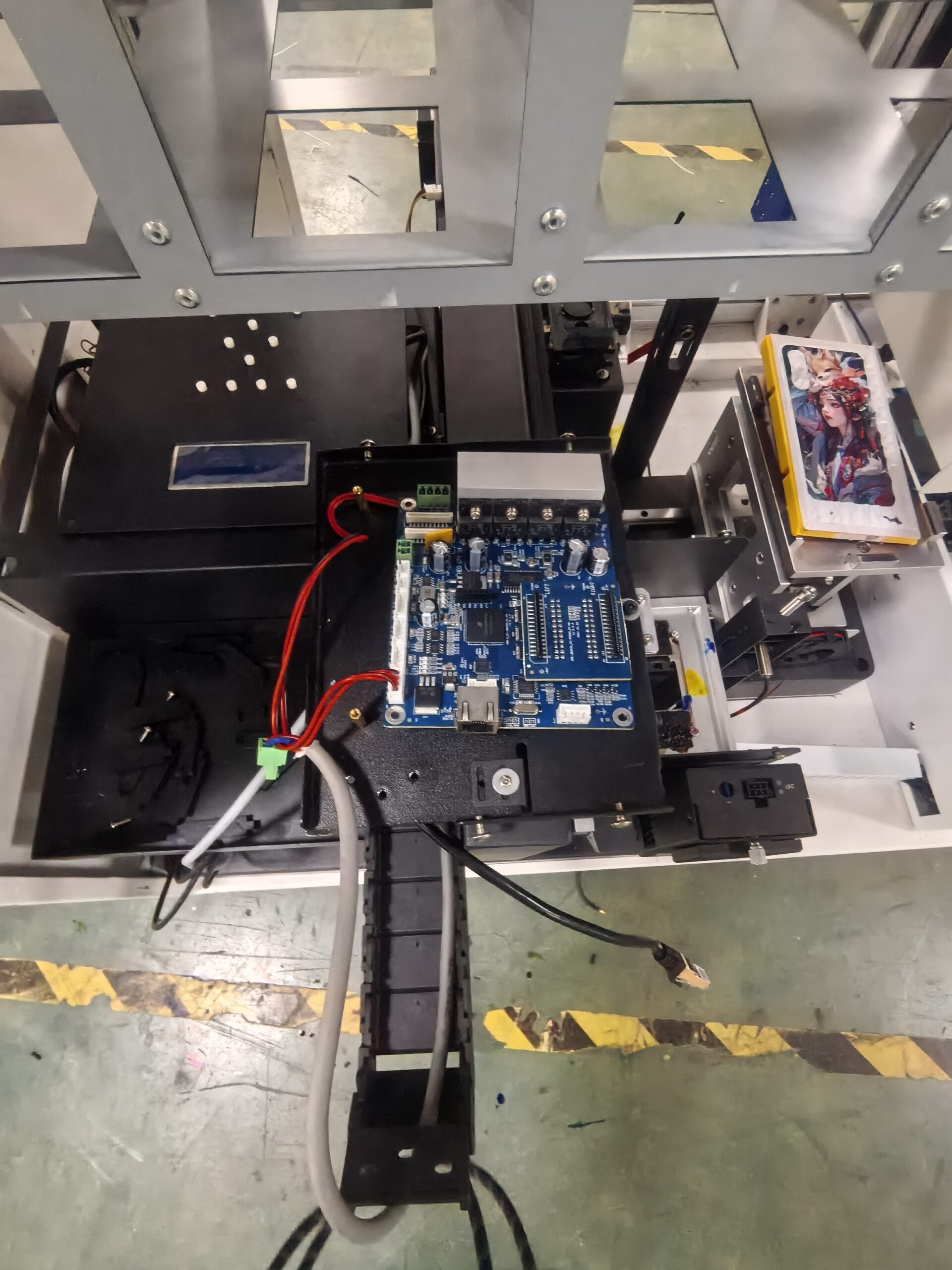

When installing a new phone case printing machine, I always warn customers to check their circuit capacity. These machines draw significant power during printing operations but use less energy during idle periods.

Phone case printing vending machines typically have two power states: active printing mode (300-500W) and standby mode (150-180W). Most machines operate on standard 220V circuits, making them compatible with typical commercial electrical systems without requiring special wiring.

Detailed Power Consumption Breakdown

Based on my experience manufacturing and monitoring hundreds of machines in the field, I can provide precise consumption data for different operational scenarios. Understanding these figures is crucial for accurate financial planning.

| Machine State | Power Draw | Daily Hours | Energy Consumption |

|---|---|---|---|

| Active Printing | 300-500W | 8 hours | 2.4-4.0 kWh |

| Standby Mode | 150-180W | 16 hours | 2.4-2.9 kWh |

| Daily Total | 4.8-6.9 kWh |

These numbers can vary based on the specific model and its feature set. For example, our PrintYOLO machines with 3D embossing capabilities may draw closer to the upper range during active printing due to the additional processing required. Machines with larger display screens for advertising will also consume slightly more power in standby mode than basic models.

The printing process itself consists of several power-intensive stages. The UV curing system demands the most electricity, as it requires high-intensity light to properly cure the ink. The mechanical components that move the print head and position the phone case also contribute to power draw, though to a lesser extent.

How Much Will Running a Phone Case Vending Machine Add to My Electricity Bill?

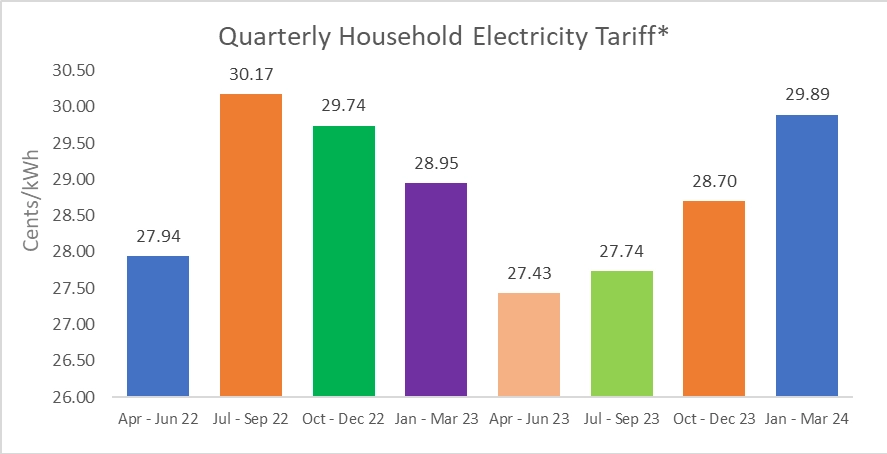

Store owners often ask me about the monthly cost impact before they commit to a machine purchase. The answer depends on your location's electricity rates and machine usage patterns.

A phone case printing machine will typically add $12-$23 to your monthly electricity bill, based on average commercial rates of $0.15/kWh. This represents a small fraction of the potential revenue, with most machines generating $1,500-$3,000 monthly in sales.

Cost Calculation Factors

When calculating your exact electricity costs, several factors will influence your final numbers. I've helped many clients work through these calculations to determine their true operating expenses.

The location-specific electricity rate is the most significant variable. Commercial rates vary dramatically by region, from as low as $0.08/kWh in some areas to over $0.30/kWh in places with high energy costs. Your specific business category and negotiated utility rates will also affect these calculations.

Usage patterns significantly impact total consumption. A machine in a high-traffic area might operate continuously during business hours, spending more time in active printing mode. Conversely, a machine in a quieter location may spend most of its time in standby, lowering the average consumption.

| Location Type | Daily Active Hours | Monthly Cost (Low Traffic) | Monthly Cost (High Traffic) |

|---|---|---|---|

| Shopping Mall | 10-12 | $18-22 | $25-30 |

| Tourist Attraction | 8-10 | $15-18 | $20-25 |

| University Campus | 6-8 | $12-15 | $18-22 |

| Retail Store | 8-10 | $15-18 | $20-25 |

Some of our clients have implemented timed shutoff systems for non-operating hours, which can reduce standby consumption by 30-40%. This is particularly beneficial for machines placed in locations with defined operating hours, such as malls or campus stores.

Can I Reduce the Electricity Consumption of My Phone Case Vending Machine?

I often hear from potential clients who are concerned about adding another power-hungry device to their already high utility bills. Fortunately, there are several effective strategies to minimize consumption.

You can reduce a phone case printing vending machine's electricity consumption by scheduling automatic shutdown during non-business hours, upgrading to newer energy-efficient models, ensuring regular maintenance, and optimizing standby settings for quieter periods.

Practical Energy-Saving Approaches

After years of helping customers optimize their operations, I've collected several proven strategies for reducing power consumption without compromising performance or customer experience.

Modern phone case printing vending machines come with built-in power management features. Our PrintYOLO models include configurable sleep settings that reduce power consumption during detected periods of inactivity. You can program these settings to match your location's traffic patterns for optimal energy savings.

Regular maintenance significantly impacts energy efficiency. Dust accumulation on cooling fans or vents forces the system to work harder, consuming more electricity. I recommend cleaning these components monthly to ensure optimal airflow and cooling efficiency. This simple maintenance step can reduce power consumption by up to 10%.

The placement of your machine also affects energy usage. Locations with direct sunlight or poor ventilation cause the cooling system to work harder. I always advise customers to position machines away from heat sources and ensure adequate airflow around all vents. This not only reduces power consumption but also extends the machine's operational lifespan.

For multi-machine deployments, staggering startup times prevents power demand spikes that might trigger higher electricity rate tiers. This approach has saved some of our larger clients hundreds of dollars annually on their utility bills.

What's the Environmental Impact of Running a Phone Case Printing Vending Machine?

With increasing focus on sustainability, many business owners ask me about the environmental footprint of these machines. It's an important consideration for both ethical business practices and customer perception.

A phone case printing vending machine produces approximately 0.5-0.9 metric tons of CO2 annually (based on average grid emissions), equivalent to driving a passenger vehicle 1,200-2,200 miles. Newer models offer improved energy efficiency, and some manufacturers offer carbon offset programs.

Sustainability Considerations

The environmental impact extends beyond just electricity consumption. When discussing sustainability with clients, I emphasize several important aspects of the operation.

The carbon footprint varies significantly based on your local electricity generation mix. Machines operating in regions with predominantly renewable energy sources will have a much lower carbon footprint than those in coal-dependent areas. Some of our customers in regions with high renewable energy penetration have calculated carbon footprints 60% lower than the average.

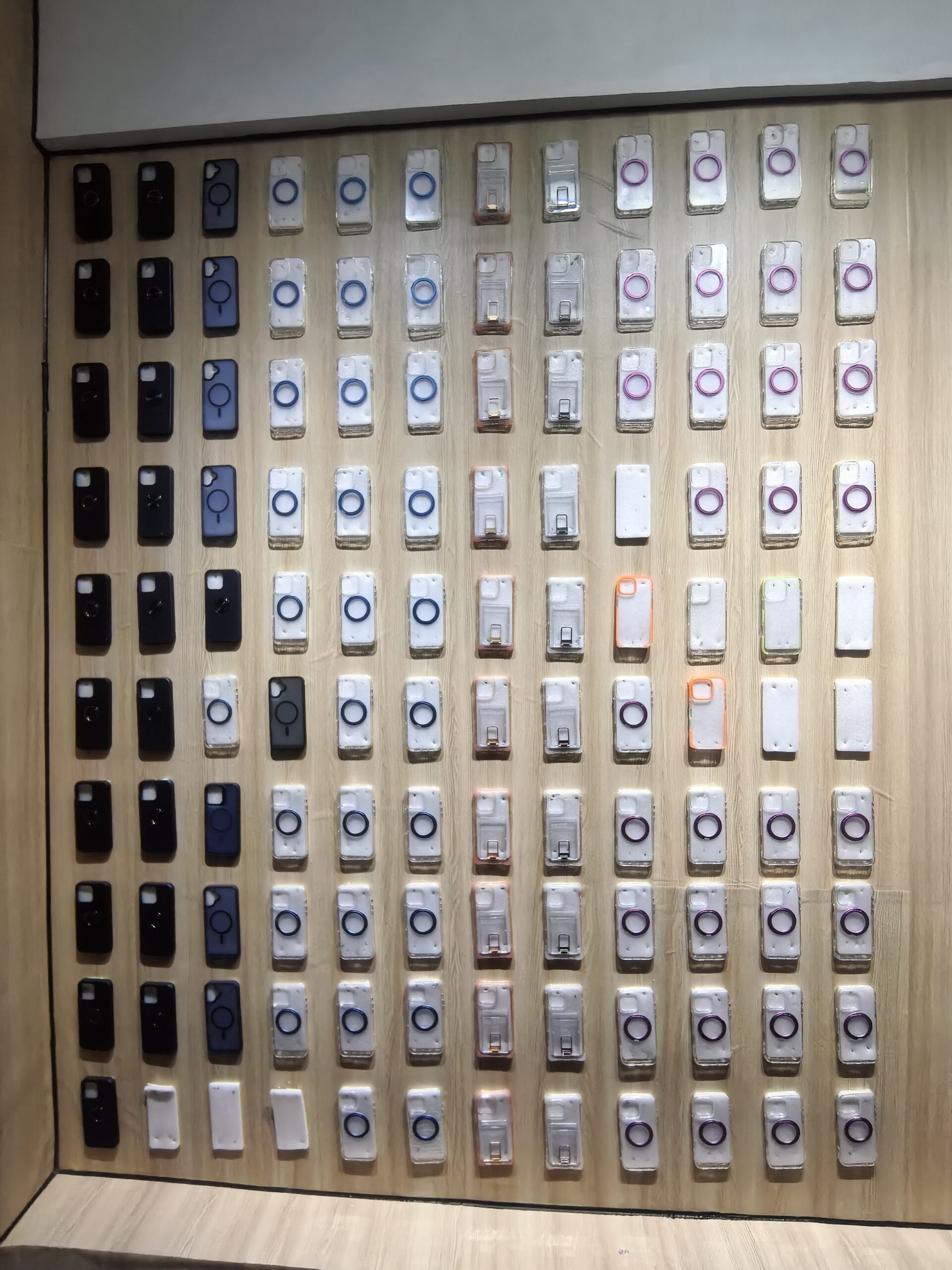

Material selection also influences environmental impact. Our PrintYOLO machines are compatible with biodegradable phone cases and eco-friendly UV inks, which significantly reduce the environmental impact of each printed case. These sustainable materials have become increasingly popular with environmentally conscious consumers.

Energy efficiency improvements continue to advance in newer machine models. Our latest generation consumes about 15% less electricity than models from just three years ago, thanks to improved UV curing technology and more efficient electronic components. These advances not only reduce operating costs but also minimize environmental impact.

Phone case printing vending machines typically use 3-5 kWh daily, costing $150-270 annually. With proper management and newer energy-efficient models, these costs can be significantly reduced while maintaining profitable operations.