How many years does a vending machine last?

I often get asked about the lifespan of vending machines. It's a key question for anyone looking to invest in this type of business. How long can you expect your machine to keep making money for you?

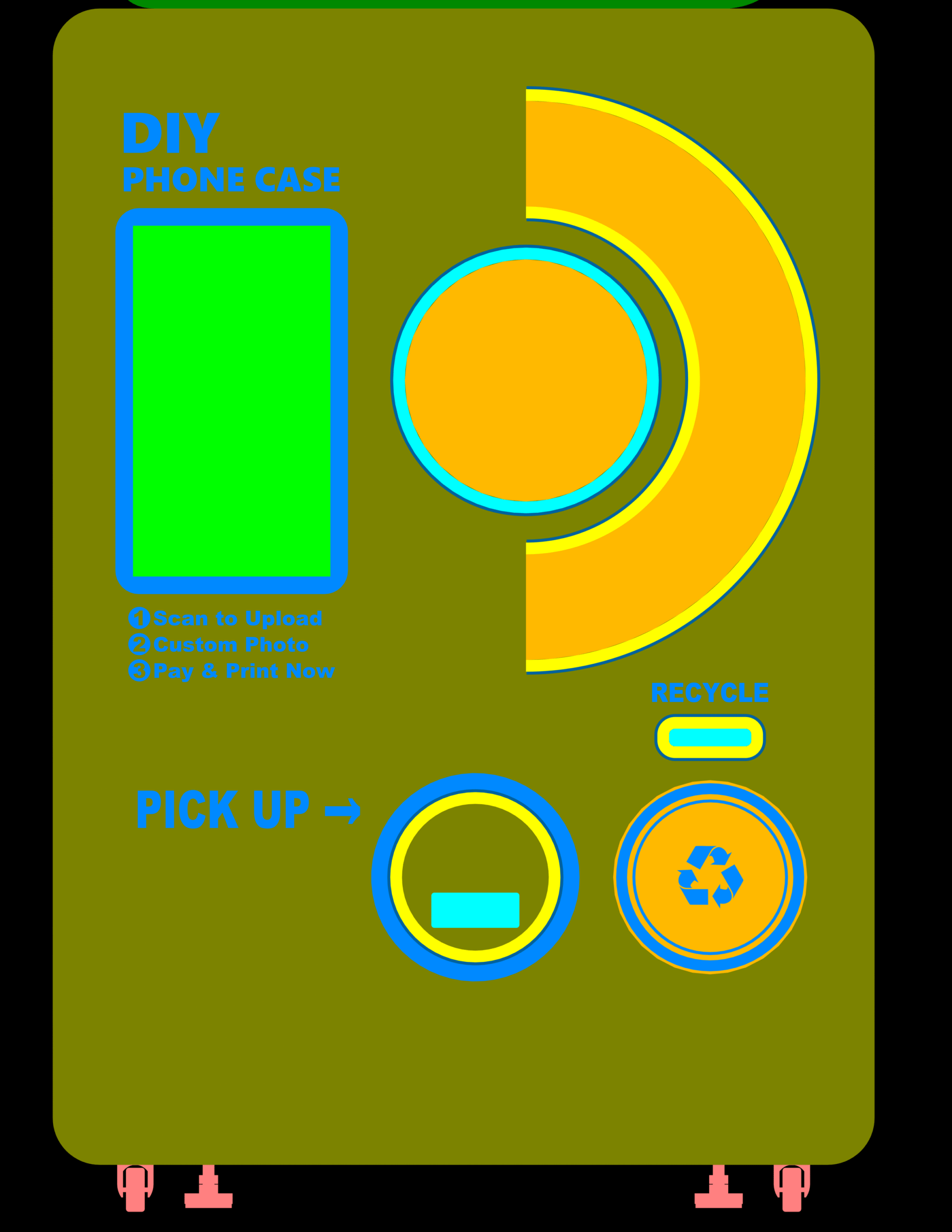

A typical vending machine can last between 10 to 20 years with proper maintenance, but the usable lifespan for profitability often ranges from 5 to 10 years due to evolving technology, changing consumer preferences, and wear and tear. My own PrintYOLO machines are built for durability and long-term operation.

When I design our PrintYOLO phone case vending machines, durability is a top priority. I want them to be reliable assets for our partners, not just short-term contraptions. So, let's break down what really makes a vending machine last.

What is the general lifespan of a vending machine?

Just like a car or any other machine, a vending machine has a lifespan. This can vary a lot. Some last longer than others. What affects this general lifespan?

The general lifespan of a traditional vending machine ranges from 10 to 20 years. Factors like the quality of parts, the environment it operates in, and the level of maintenance it receives heavily influence how long it remains functional, but older machines may not be profitable.

From my experience with industrial machines, the physical structure of a vending machine, especially those made from sturdy metal, can often last 15 to 20 years. The strength of the outer casing helps protect the inner workings. However, the internal parts are what usually wear out first. These include things like motors, sensors, and payment systems. If a machine is in a place where it's used very often, like a busy airport, its parts will wear out faster than if it's in a quieter office building. Heat, humidity, and dust can also shorten the life of electronic parts. Poor quality parts will break down sooner. If a machine gets bumps or knocks, either from people or during transport, that can also reduce its lifespan. My PrintYOLO machines are built with industrial-grade parts, which are made to last longer under heavy use. We choose robust components because I know our machines will be in high-traffic areas. Also, simple things like keeping the machine clean and checking its parts regularly can add many years to its operation. An old rule of thumb for durability in equipment is that you get what you pay for; cheaper machines usually use cheaper parts and don't last as long.

| Component | Typical Lifespan (Years) | Impact on Overall Machine Lifespan |

|---|---|---|

| Outer Casing / Structure (Metal) | 15-20+ | Very durable, rarely fails |

| Motors / Dispensing Mechanisms | 5-10 | Can wear out with heavy use |

| Electronic Boards / Control Systems | 7-12 | Sensitive to environment, power issues |

| Payment Systems (Card Readers, etc.) | 5-8 | Subject to constant use and updates |

| Touchscreens / Displays | 5-10 | Can degrade over time, prone to damage |

What factors affect the profitable lifespan of a modern vending machine?

A machine might still "work" but not make money. This is the difference between physical lifespan and profitable lifespan. For a modern, high-tech machine like ours, many things can shorten its period of making good income.

The profitable lifespan of a modern vending machine, especially a high-tech one like a phone case printer, is usually 5 to 10 years. This shorter period is due to rapid changes in technology, evolving customer preferences (e.g., payment methods, phone models), and increasing competition requiring features updates to stay relevant.

This is the most important part for me as a business owner. A machine can be physically sound, but if it no longer attracts customers, it's not profitable. Modern vending machines, like our phone case printers, depend heavily on technology. Phone models change every year. Payment methods evolve quickly; people now expect Apple Pay or QR codes. If your machine can't handle the newest phone models or the latest payment, it starts losing sales. That means it loses profit. Also, customer expectations change. People want new features, better graphics, faster service. If a competitor comes along with a much newer machine, your older one might look outdated and less appealing. This makes it harder for your machine to stay competitive. So, even if the motors still work, if the screen is old, or the software is slow, it won't earn as much. My focus at PrintYOLO is to build machines that can be updated. We design them so parts, like the printing module or payment system, can be replaced or upgraded. This helps extend the profitable lifespan beyond just the physical one, keeping them attractive and functional for customers for longer.

| Factor | Impact on Profitable Lifespan | My Strategy at PrintYOLO |

|---|---|---|

| Technology Obsolescence | Outdated software, hardware reduces appeal | Modular design, upgradable components (e.g., phone models, payment systems) |

| Changing Consumer Preferences | Demand for new features, payment methods | Remote software updates, customizable user interface |

| Wear and Tear / Maintenance Costs | Frequent breakdowns increase operating costs | Industrial-grade components, robust build quality, remote monitoring |

| Competition | Newer machines offer better features | Continuous R&D, offer advanced features (e.g., AI recommendations) |

| Regulatory Changes | New payment standards, accessibility laws | Designed for flexibility, compliant with international standards |

How does maintenance affect how long a vending machine runs?

Just like any valuable asset, a vending machine needs care. If you don't look after it, it won't last as long. Regular maintenance is key to keeping it running well and making money.

Proper and consistent maintenance is crucial for maximizing a vending machine's lifespan, both functional and profitable. Regular cleaning, timely repair of minor issues, and proactive replacement of worn parts significantly reduce downtime, extend operational life, and ensure smooth customer experience.

I always tell our partners: "Treat your machine like an investment." Neglecting maintenance is like throwing money away. Small problems can quickly become big, expensive ones. For instance, sensors might get dirty from dust or ink, causing them to misread. If you clean them regularly, they work fine. If not, the machine malfunctions, and customers walk away. Motors can get noisy or slow. Catching this early and servicing them extends their life. Ignoring it means total breakdown and a more expensive fix. The payment system, especially card readers, needs routine checks because they get heavy use. Keeping software updated is also a form of maintenance. Bugs can be fixed, and new features added, all extending the profitable life. When I hear about a machine that only lasted a few years, it's often due to poor maintenance, not a fault in the machine itself. My PrintYOLO machines allow for remote monitoring, so owners can proactively identify potential issues before they cause downtime. This proactive approach saves a lot of money and builds customer trust by ensuring the machine is always working.

| Maintenance Task | Description | Impact on Lifespan & Profitability |

|---|---|---|

| Regular Cleaning | Wiping surfaces, cleaning sensors, vents | Prevents dust buildup, ensures proper sensor function, improves appearance |

| Part Inspection | Checking motors, belts, connections | Identifies wear before failure, prevents larger repairs |

| Software Updates | Applying latest firmware and patches | Ensures compatibility, security, introduces new features |

| Consumable Checks | Monitoring ink levels, blank case supply | Prevents stockouts, ensures continuous operation |

| Preventative Repair | Addressing minor issues before they worsen | Reduces costly breakdowns, extends component life |

How do environmental factors and usage rate impact lifespan?

Where a machine is located and how often it's used can change how long it lasts. Extreme conditions or constant use can wear a machine out faster. I factor this in when advising on placement.

Environmental factors like extreme temperatures, humidity, and dust, along with the machine's usage rate (how many transactions per day), significantly impact its lifespan. Machines in harsh conditions or high-traffic areas tend to wear out faster than those in stable, less active environments.

Imagine running a machine 24/7 in an airport versus a small office. The airport machine will naturally see more wear. High usage means motors work harder, payment systems get more swipes, and screens get more touches. This directly shortens the life of moving parts. Temperature is also a big deal. If a machine is in a very hot place, like direct sunlight in a window through summer, the electronics can overheat and degrade faster. Very cold places can make materials brittle and affect fluid systems (like ink). Humidity can cause corrosion and electronic shorts over time. Dust and dirt can accumulate in vents and moving parts, leading to breakdowns. I always advise on finding locations with stable climates where possible. While our machines are built tough for various conditions, optimal environments help them last longer. Knowing the usage rate helps predict when parts might need replacing. For example, if a machine does 100 transactions a day, its parts will likely wear out faster than one doing 10 transactions. This insight helps in planning maintenance schedules and setting realistic expectations for machine replacement cycles. My machines are designed for high throughput, but even the best machines benefit from a controlled environment.

| Factor | Impact on Machine Lifespan | Mitigating Strategies (My Approach) |

|---|---|---|

| High Usage Rate | Faster wear on mechanical components, payment systems | Use industrial-grade components, design for high cycle counts |

| Extreme Temperature | Overheating electronics, brittle parts, fluid issues | Use robust cooling systems, recommend stable indoor locations |

| High Humidity | Corrosion, electronic shorts | Use moisture-resistant components, sealed electronics |

| Dust/Dirt | Clogs vents, interferes with sensors, grinds moving parts | Design with sealed components, provide cleaning guidelines |

| Vandalism/Abuse | Physical damage to exterior and interior | Use durable materials, recommend secure locations with cameras |

A vending machine can physically last 10-20 years, but its profitable lifespan is typically 5-10 years due to technology and trends. Proper maintenance and strategic placement are key for maximizing operational life and returns.